Avoiding Scale-Up Pitfalls: Common Mistakes in Advanced Automation

When your business automation breaks at 3 AM, duplicating customer records across 86 accounts and triggering a cascade of incorrect invoices, you learn an expensive lesson: speed without strategy is just expensive chaos.

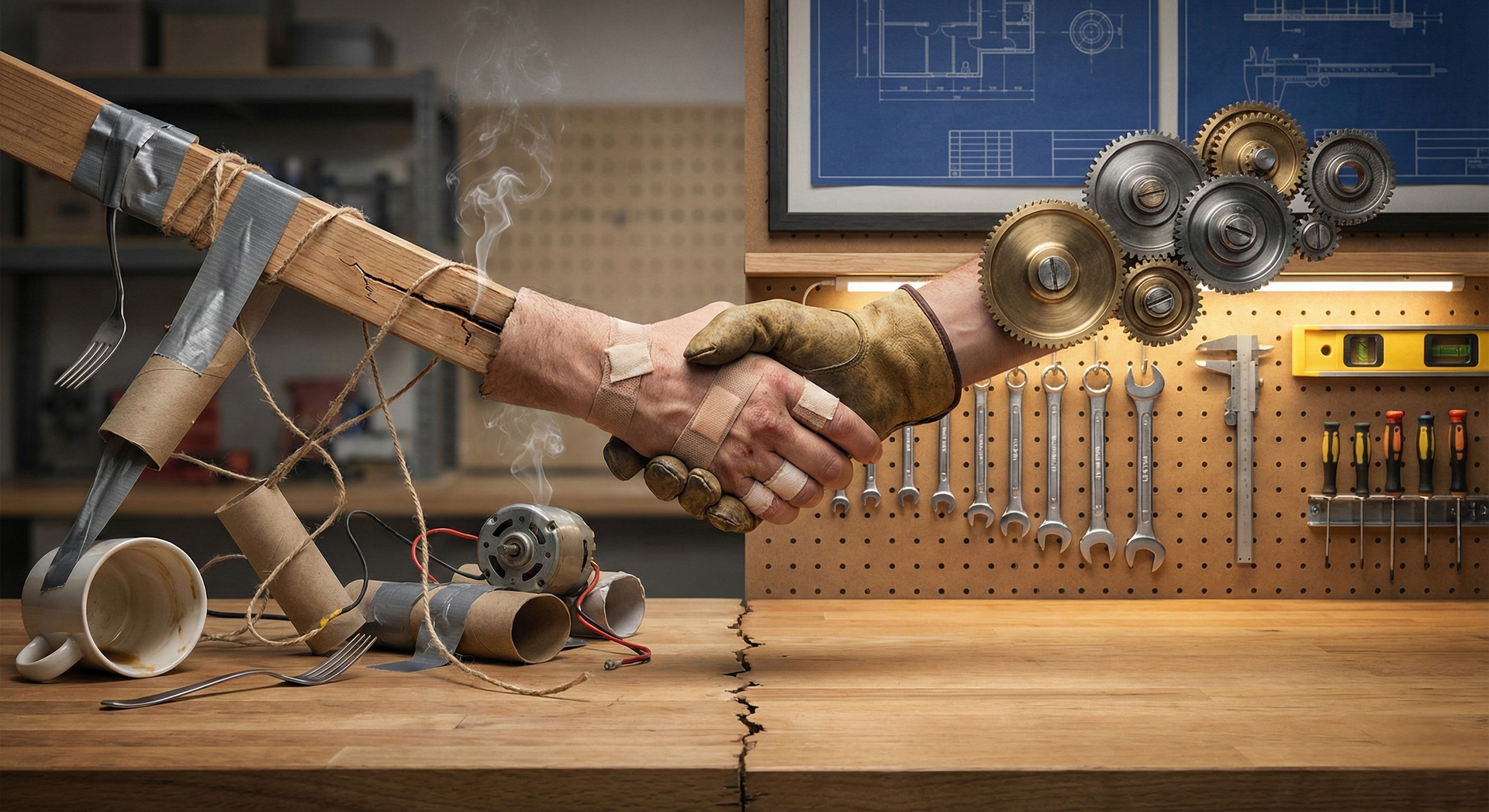

This isn't a hypothetical scenario. It's the kind of wake-up call that happens when small and medium-sized businesses rush into automation without laying the proper groundwork. The promise of automation is seductive, but the reality is more nuanced. Automating a broken process doesn't fix it; it just breaks things faster and at greater scale.

The Automation Paradox

Here's the uncomfortable truth: most automation failures aren't technical problems. They're strategic ones.

The automation paradox is this: the same characteristics that make automation powerful (speed, consistency, scale) make poorly designed automation catastrophic. What takes a human hours to mess up, automation can accomplish in seconds across thousands of records.

The Five Critical Mistakes

1. Automating Before Optimizing

The most common pitfall is automating your current process without questioning whether it's the right process. If your manual workflow involves checking three different spreadsheets, sending two confirmation emails, and then manually updating a database, automating that exact sequence just means you'll do inefficient work faster.

The Countermeasure: Process mapping comes first. Before writing a single automation rule, document your current process visually. Identify bottlenecks, redundancies, and decision points. Ask: "If we were designing this from scratch today, knowing what we know, how would we do it?" Only then should you automate.

Look for steps that exist only because of historical limitations or previous workarounds. Often you'll discover that entire segments of your workflow can be eliminated rather than automated.

2. The Documentation Desert

Automation without documentation is a ticking time bomb. When the person who built the automation leaves, gets promoted, or simply forgets the logic they implemented six months ago, the organization is left with a black box that everyone's afraid to touch.

Consider what happens when an automated workflow starts behaving strangely. Without documentation, troubleshooting becomes archaeological work: digging through code, testing scenarios, and hoping you don't break something else in the process.

The Countermeasure: Documentation isn't optional; it's part of the automation itself. For every automated workflow, document:

- Purpose and scope: What business problem does this solve?

- Trigger conditions: What starts this automation?

- Data flow: What information moves where, and how is it transformed?

- Decision logic: What rules determine different outcomes?

- Dependencies: What other systems, automations, or data sources does this rely on?

- Failure modes: What could go wrong, and what happens when it does?

- Maintenance schedule: When should this be reviewed or updated?

When your automation breaks, good documentation is the difference between a five-minute fix and a five-hour crisis.

3. Insufficient Testing at Scale

Testing an automation with three records is not the same as testing it with three thousand. Many automation failures emerge only at scale, when edge cases that seemed unlikely become statistical certainties.

The Countermeasure: Implement staged rollouts with progressively larger test groups. Start with 10 records, then 100, then 1,000. Monitor closely at each stage. Use realistic test data that includes edge cases: unusual names, special characters, null values, maximum field lengths, and duplicate entries.

Build in safeguards from the start. Set maximum batch sizes so a single failure can't cascade across your entire dataset. Implement circuit breakers that pause automation if error rates exceed a threshold. Create manual review checkpoints for high-stakes actions like financial transactions or customer communications.

4. The Training Gap

Even the most elegant automation will fail if the people who interact with it don't understand how it works. This includes managers who need to monitor performance, IT staff who handle troubleshooting, executives who make decisions based on automated reports, and of course end users.

When people don't understand the underlying logic of an automation, they can't distinguish between the system working correctly and the system malfunctioning. They may assume something is broken when it's actually following its rules, or worse, assume everything is fine when something actually is broken.

The Countermeasure: Training should cover three levels:

- Operational training: How do I use this? What buttons do I click?

- Conceptual training: How does this work? What rules is it following?

- Troubleshooting training: What should I check when something seems wrong?

Equally important: train people on what the automation doesn't do. Many failures stem from incorrect assumptions about an automation's scope or capabilities.

5. Set-It-and-Forget-It Syndrome

Automation is not a one-time project; it's an ongoing system that exists in a changing environment. Business processes evolve. Software updates introduce new features or break old integrations. Data structures change. Regulatory requirements shift.

Without regular maintenance and monitoring, automations that once worked perfectly can silently begin producing incorrect results as the world around them changes.

The Countermeasure: Treat automation as infrastructure that requires maintenance:

- Implement comprehensive logging: Record every automation run, including inputs, outputs, and any errors or warnings. Structure logs so they're searchable and analyzable.

- Set up intelligent alerts: Don't just alert on failures. Alert on unusual patterns: unexpected volume changes, longer processing times, higher error rates, or suspicious data patterns. A sudden spike in "successful" automation runs might indicate a looping error rather than legitimate activity.

- Schedule regular reviews: Quarterly, review each automation's performance. Is it still solving the right problem? Is it still using the optimal approach? Have business requirements changed?

- Monitor upstream and downstream: Your automation doesn't exist in isolation. Changes in source data quality or downstream system capacity can affect reliability without triggering any errors in your automation itself.

The Strategic Framework: Building for Scale

Moving from simple automation to reliable, scaled automation requires a strategic shift in how you approach design and implementation.

Start with Architecture, Not Implementation

Before building, map out your automation ecosystem. Which processes connect? Where does data flow? What are the dependencies? This architectural view helps you spot potential conflicts, identify opportunities for consolidation, and design for resilience.

Consider the impact when multiple automations pull data from the same source system. A change in that system's API structure could break all dependent automations simultaneously. An architectural approach might create a single integration layer, isolating the impact of future changes.

Design for Observability

Build automation that tells you how it's performing. Include checkpoints that validate data quality at each transformation step. Log decision points so you can audit why specific actions were taken. Create dashboards that surface key metrics: volume processed, error rates, processing time, and data quality indicators.

When problems occur, and they will, observability is the difference between "something's wrong but we don't know what" and "the error rate on the customer import workflow spiked at 2:37 PM when a malformed CSV was uploaded."

Implement Graceful Degradation

Resilient automation doesn't just work when everything's perfect; it degrades gracefully when things go wrong. Build in fallback mechanisms: if the primary API is unavailable, can you queue requests for later? If data validation fails, can you flag items for manual review rather than processing them incorrectly?

Version Control and Rollback Capability

Treat automation like code, because it is. Use version control so you can track changes, understand why modifications were made, and roll back if an update causes problems. When an automation that's been stable for months suddenly starts failing, the ability to see what changed is invaluable.

The Real-World Reliability Test

Here's a practical test for whether your automation is ready to scale: Could someone unfamiliar with it understand what it does, troubleshoot a problem, and modify it safely using only the documentation and logs?

If the answer is no, you're not ready to scale. You have a dependency on specific knowledge held by specific people. That's a single point of failure.

Moving Forward

The goal is to implement automation that actually delivers on its promise of efficiency, consistency, and scalability. That requires patience, planning, and a recognition that the real work is in designing robust systems, not so much in configuring tools.

Start small, document everything, test thoroughly, and scale deliberately. When you encounter failures, treat them as learning opportunities. The companies with the most reliable automations are the ones that build systems designed to catch, contain, and learn from inevitable errors.

Automation amplifies your processes. Make sure you're amplifying the right things.

The path to reliable automation isn't faster; it's more thoughtful. But thoughtful automation at scale beats manual processes every time, and it definitely beats automated chaos at 3 AM.

© Virtual Rani2025. The information contained herein is provided for information purposes only; the contents are not intended to amount to advice and you should not rely on any of the contents herein. We disclaim, to the full extent permissible by law, all liability and responsibility arising from any reliance placed on any of the contents herein.